Top 10 Features to Look for in a Quality Flame Photometer

Introduction to Flame Photometers

What is a Flame Photometer?

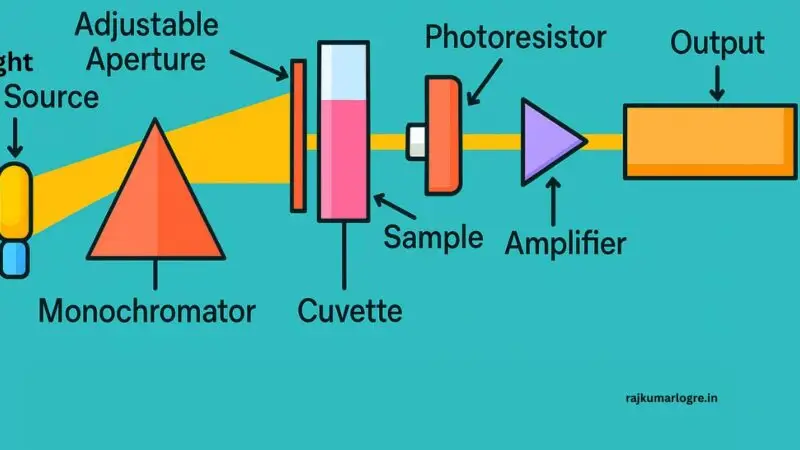

A flame photometer, also known as a flame atomic emission spectrometer, is a scientific instrument used to detect and quantify specific metal ions—mainly sodium, potassium, lithium, and calcium—based on their emission of light at specific wavelengths when introduced into a flame. It’s widely used in clinical labs, food industries, agriculture, and chemical research. The working principle relies on the excitation of metal atoms in a flame, which then emit radiation at characteristic wavelengths that can be measured and quantified.

These devices are indispensable in quality control, especially in fields like medical diagnostics and fertilizer manufacturing. Their simplicity, speed, and accuracy make them a go-to tool for elemental analysis where only a few elements are of interest.

Importance of Flame Photometers in Modern Labs

Why are flame photometers still a cornerstone of many labs despite the rise of more complex analytical tools like ICP-OES or AAS? It comes down to cost-effectiveness, user-friendliness, and high throughput. In routine applications where only a limited set of elements need to be measured quickly and reliably, a flame photometer is ideal.

Additionally, they require less training to operate, are less prone to interference, and offer rapid analysis—features that many resource-constrained labs rely on. From hospital labs determining electrolyte levels in blood to agricultural labs monitoring soil nutrient content, flame photometers provide unmatched utility.

1. High Sensitivity and Accuracy

Why Sensitivity Matters in Flame Photometry

When you’re dealing with trace elements, especially in clinical diagnostics or environmental monitoring, every nanogram counts. High sensitivity ensures that even the smallest concentrations of a target ion like potassium or calcium can be detected and quantified reliably. A quality flame photometer should offer a detection limit that suits your specific applications—some models can go as low as 0.1 ppm or even lower for sodium and potassium.

A highly sensitive instrument minimizes false negatives and ensures data integrity. This is critical in fields like medical diagnostics, where missing a low potassium level could mean missing an early sign of a health issue. For labs handling a broad range of sample types—whether serum, plant tissue, or water—sensitivity directly influences accuracy and credibility.

How to Evaluate Accuracy in Readings

Accuracy in flame photometry is about how close the measured value is to the true concentration of the analyte. It’s not enough for a photometer to be sensitive; it must also deliver readings that you can trust. Accuracy is often improved through proper calibration, stable flame conditions, and minimal background noise.

Look for features like built-in calibration curves, real-time drift correction, and temperature compensation. Also, a photometer with a high signal-to-noise ratio will typically offer better accuracy. Reproducibility of results is another good indicator—if the same sample yields wildly different values, it’s a red flag.

To wrap it up, when shopping for a flame photometer, don’t just ask, “How low can it go?” Ask, “How consistently can it hit the bullseye?”

2. Multi-Element Detection Capability

Advantages of Detecting Multiple Elements

Calcium, potassium, and sodium required different studies since traditional flame photometers frequently measured one element at a time. But modern models offer simultaneous multi-element detection, which significantly boosts productivity and reduces workload.

Imagine running a blood serum test for sodium, potassium, and lithium all at once—that’s a time-saver. Multi-channel detectors allow multiple wavelengths to be monitored simultaneously, drastically cutting down on analysis time. In high-volume labs, this translates to lower operational costs and quicker turnaround times.

Elements Commonly Measured Simultaneously

Most advanced flame photometers today can simultaneously detect and measure:

- Sodium (Na)

- Potassium (K)

- Calcium (Ca)

- Lithium (Li)

- Barium (Ba)

Depending on the model and configuration, some devices even allow custom channel options. This makes them flexible enough for specialized fields like petrochemistry or beverage analysis, where unusual ions might need routine monitoring.

Whether you’re measuring electrolyte levels in a hospital or checking salt content in processed foods, a multi-element flame photometer is a solid investment.

3. Digital Display and User Interface

The Role of Intuitive Interfaces in Efficiency

Ever been stuck with a piece of lab equipment that feels like decoding hieroglyphics? A user-friendly interface can be a game-changer. A digital flame photometer with an intuitive touchscreen or LCD panel reduces human error, enhances ease of use, and makes training new users a breeze.

Modern interfaces often include guided calibration steps, real-time graphing, and menu-based navigation. These features are particularly helpful in academic settings or multi-user labs where not everyone is a seasoned analyst.

Features That Enhance User Experience

Look for:

- Backlit, high-contrast displays that are easy to read in any lighting

- Multi-language support, especially useful in global labs

- Touchscreen controls for quick parameter adjustment

- Preloaded methods to speed up routine testing

- Error prompts and alerts for flame failure, low fuel, etc.

An intuitive UI doesn’t just improve workflow—it increases confidence in your results. After all, the fewer the steps, the fewer the chances for errors.

4. Calibration and Standardization Functions

Automatic vs Manual Calibration

Calibration is the backbone of any analytical instrument, and flame photometers are no exception. Manual calibration might work in a pinch, but it leaves too much room for inconsistency. That’s why automatic calibration is a top feature to seek out.

High-quality photometers come with automatic calibration routines that reduce user dependency and improve repeatability. Some units even feature auto-zeroing and internal standards to adjust for drift, ensuring each reading is as close to perfect as possible.

Importance of Standard Curve Memory

Many flame photometers now include built-in memory for calibration curves, saving you the hassle of recalibrating each time. This is a godsend in busy labs handling repetitive testing.

Stored calibration curves allow for:

- Faster setup and sample analysis

- Reduced errors from recalibration

- Consistent results across multiple users

With pre-set curve storage, technicians can simply select the required method, and the instrument adjusts accordingly.

5. Data Logging and Connectivity Options

USB, Bluetooth, and Cloud Sync Capabilities

In today’s data-driven world, the ability to store and share results quickly is a must. Flame photometers with USB ports, Bluetooth, or Wi-Fi options let you connect to PCs, lab management systems, or even cloud storage.

Data transfer becomes seamless, cutting down on paperwork and transcription errors. Some advanced systems even offer real-time data monitoring through mobile apps.

Benefits of Real-Time Data Storage

Real-time data logging:

- Ensures traceability of samples and results

- Enables trend analysis for long-term monitoring

- Improves regulatory compliance by maintaining a verifiable digital record

Having digital records also means faster audits and easier troubleshooting if anomalies arise.

6. Sample Throughput and Speed

How Fast Analysis Impacts Lab Productivity

In any laboratory setting—especially in high-throughput environments like clinical diagnostics or industrial quality control—the speed at which a flame photometer processes samples can significantly impact overall efficiency. A photometer that takes too long per sample not only slows down operations but also leads to potential bottlenecks in workflows.

Modern flame photometers are designed with enhanced sample throughput in mind. Whether it’s by optimizing the burner design, refining the nebulizer system, or automating sample aspiration, manufacturers are pushing for quicker, more seamless operations. Some instruments can process dozens of samples per hour, dramatically increasing lab output.

Speed doesn’t just mean faster results—it also translates to reduced waiting times for critical data. Imagine a hospital lab waiting on electrolyte results for ICU patients; even a few minutes saved per test can make a real difference.

Comparison of Sample Injection Systems

It relates to how samples are introduced into the flame using a flame photometer. There are primarily three types of systems:

- Manual aspiration: Requires an operator to introduce samples manually—suitable for low-volume labs.

- Auto-samplers: Automated systems that feed samples sequentially, saving time and reducing human error.

- Flow injection systems: Offer the highest throughput, continuously feeding the sample to the flame for ultra-fast analysis.

Auto-samplers and flow injection systems are particularly useful in large-scale operations where hundreds of samples need processing daily. Purchasing a unit with an injection system that works with it can overhaul lab productivity.

7. Safety Features and Compliance

Built-In Safety Protocols

Working with flames, gases, and chemicals always carries a degree of risk. That’s why high-quality flame photometers are equipped with built-in safety mechanisms to prevent accidents and protect users.

Key safety features to look for:

- Flame failure detection: Automatically shuts off fuel supply if the flame goes out.

- Over-temperature protection: Prevents overheating of sensitive components.

- Gas leak sensors: Alerts users to potential leaks from fuel lines.

- Lockout modes: Restricts unauthorized use, especially in educational settings.

These safety protocols are not just about protecting hardware—they’re about keeping people safe and operations smooth. Look for models that meet international safety standards for peace of mind.

Certifications and Regulatory Compliance

A good flame photometer should adhere to relevant safety and quality standards. Certifications like:

- ISO 9001 for quality management

- CE marking for conformity with EU safety standards

- RoHS compliance indicating restricted use of hazardous materials

Such certifications ensure that the device has passed rigorous testing and meets legal requirements for operation in regulated industries. If your lab works under strict regulatory oversight—such as in pharmaceuticals or environmental testing—these certifications are non-negotiable.

8. Compact Design and Portability

Space Efficiency in Lab Environments

Not every lab has the luxury of ample bench space. Compact instruments that still pack a punch in terms of performance are in high demand. A space-saving design allows labs to maximize their existing infrastructure and make room for other critical tools and processes.

Modern flame photometers are becoming more ergonomic, with smaller footprints and modular builds. These features allow labs to fit the instruments into tight spaces without compromising performance. In addition, a compact design often translates to easier maintenance and better workflow integration.

Portable Models vs Benchtop Versions

The demand for portable testing solutions is growing, especially in fields like agriculture, environmental monitoring, and food safety. Portable flame photometers are ideal for on-site analysis where transporting samples to a central lab is not feasible.

While benchtop models offer higher performance, precision, and more features, portable units provide unmatched convenience and mobility. Many portable flame photometers come with rechargeable batteries, lightweight designs, and intuitive displays for quick testing in the field.

Depending on your particular use case, you can choose between benchtop and portable. If you need mobility and quick results on-site, go portable. For more comprehensive, multi-element, and high-accuracy testing, a benchtop model is the way to go.

9. Ease of Maintenance and Durability

Maintenance Schedules and User Guidelines

Maintenance is a key part of keeping your flame photometer running smoothly. Quality instruments come with clear maintenance schedules and guidelines, ensuring users can handle routine upkeep without needing a service technician for every minor issue.

Check if the manufacturer provides:

- User manuals with detailed instructions

- Training videos or online tutorials

- Diagnostic alerts and system checks

Preventive maintenance, like regular cleaning of burners and checking gas lines, can extend the life of the machine. Units that offer easy access to components and tool-free maintenance points are especially appreciated in busy labs.

Build Quality and Warranty Considerations

Durability matters, particularly when you’re investing thousands into a scientific instrument. A sturdy build—typically using corrosion-resistant metals and high-grade plastics—ensures longevity even under demanding lab conditions.

Before buying, ask:

- Is the frame resistant to chemical splashes?

- Are key parts (like the burner or nebulizer) made from durable, replaceable materials?

- What kind of warranty does the manufacturer offer?

A solid warranty, ideally covering 2-5 years, speaks volumes about the manufacturer’s confidence in their product. Some even include service plans for free calibration and emergency support.

10. Cost-Efficiency and Value for Money

Balancing Features with Budget

Let’s face it—budgets are always a consideration. However, the least affordable choice isn’t always the best one. A low-cost flame photometer might seem like a steal until it requires frequent repairs, produces unreliable results, or lacks essential features.

Instead, focus on value for money. Ask yourself:

- Does the tool meet your needs for testing purposes now and in the future?

- Will it reduce labor and analysis time?

- How much will maintenance and consumables cost?

A slightly higher upfront investment in a quality instrument often pays off in reduced downtime, fewer repairs, and better data integrity.

Total Cost of Ownership

When assessing cost-efficiency, don’t just consider the purchase price. Look at the total cost of ownership over 5–10 years:

- Initial cost

- Consumables and spare parts

- Service and maintenance fees

- Energy and gas usage

- Downtime impact

A good flame photometer pays for itself by enhancing lab productivity, ensuring accurate results, and minimizing recurring expenses. In the long run, performance and reliability always trump low price tags.

FAQs

What elements can be detected with a flame photometer?

Typically, flame photometers can detect sodium (Na), potassium (K), lithium (Li), calcium (Ca), and barium (Ba), depending on the model and configuration.

How often should a flame photometer be calibrated?

Calibration frequency depends on usage, but daily calibration is recommended for high-precision environments, especially clinical and research labs.

Is a digital flame photometer better than an analog one?

Yes. Digital photometers provide more accurate readings, easier data logging, and better user interfaces compared to analog models.

Can I use a flame photometer in a mobile lab setup?

Of course. There are portable flame photometers that are perfect for investigation, on-site testing, and transportable labs.

What’s the average lifespan of a quality flame photometer?

With proper maintenance, a high-quality flame photometer can last 7–10 years or more.